Asuzac Fine Ceramics

As a leading supplier of ceramic wafer hands to semicon processing industry,

ASUZAC is making endless efforts to develop advanced technology that satisfies the needs of the customers.

We "ASUZACKers" value trust and teamwork to briskly respond to customers' voice

and take quick action, pursuing environmental friendliness and mutual prosperity

among customers, communities, and societey as a whole.

We have years of experience in having supplied quality ceramic arms, shields, rings, trays and porous chucks which we belive added new values to the processes of semicon fabrication including Wafer Handling, Photolithography, Dry Etching, CVD, Cleaning, and more. Here are our 4 unparalled advantages that we ensure will help enhance your processes.

We are a leading maker of ceramics end effector or 'Hand' for wafer transportation in an atmospheric and vacuum environment.

Our product lineup is varied enough to meet your quality requirement. These standard hands are kept in stock and ready to meet your urgent need.

The technique of createing a hollow air channel inside a single-piece body of ceramics is originated by ASUZAC.

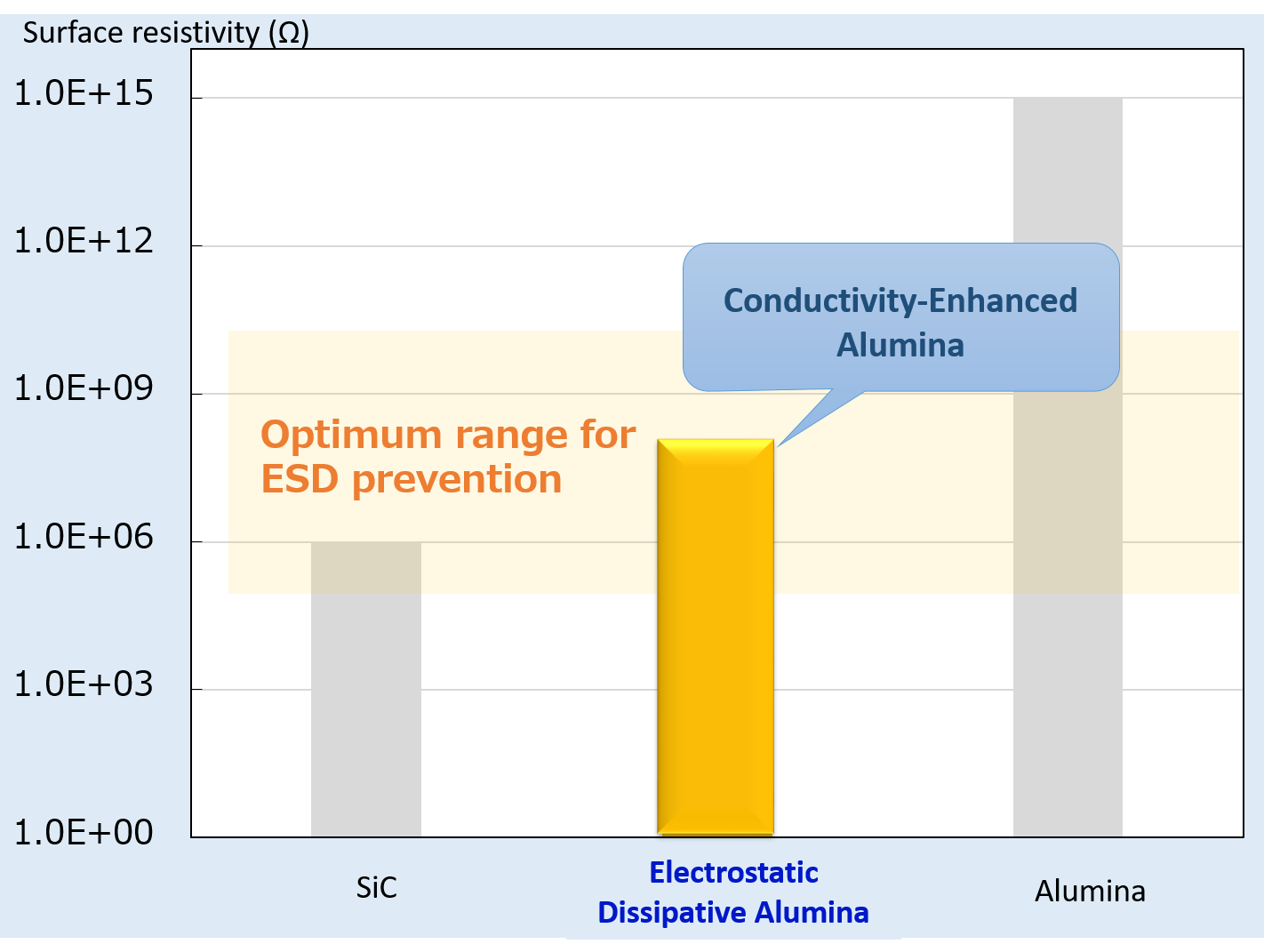

* ESD: Electro Static Discharge

ASUZAC Inc. has developed a new type of alumina that can dissipate static electricity away from the end effector surface.

This new electrically conductive alumina can serve as an ESD preventative option.

| Length (mm) |

Width (mm) |

Thickness (mm) |

|

|---|---|---|---|

| Wide parts | 1450 | 1300 | 20 |

| Long parts | 4000 | 70 | 50 |

| Thick parts | 1500 | 100 | 60 |

| Wide and thick parts | 670 | 550 | 30 |

Up to 4 meers in length with seamless construction

We are capable of manufacturing large-sized, long & narrow alumina products which are integral parts of your Flat Panel Display and OLED processing equipments.

Our competitive edge is to be able to make those kinds of large products at low cost by casting method.

Collaborative Creation is our motto. ASUZAC can customize materials into various shapes and sizes accoridng to your needs and application. Just send us your drawing or rough idea and then we can start from there! ASUZAC is willing to think and work together to bring to you the best solution through online discussion via Teams and Zoom.

981 Nakayama, Takayama-mura

Kamitakai-gun, Nagano-ken

382-8508, Japan

Mon.- Friday

8:00AM - 5:00PM

Copyright (C) 2021 ASUZAC. All Rights Reserved.